Engine Remanufacturing

Engine Remanufacturing in Atlanta, GA

Enduring Performance and Lasting Results

Affordable Engine Remanufacturing Services

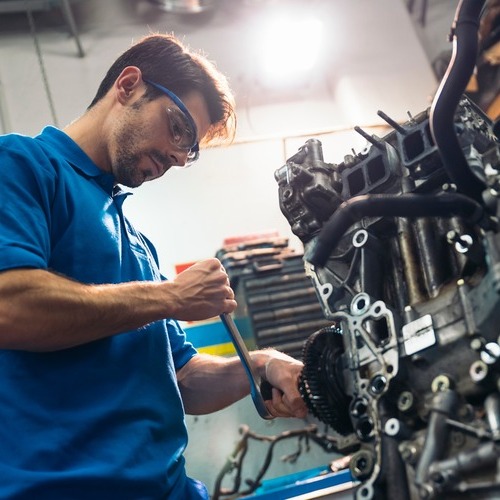

Our engine remanufacturing process begins with a thorough cleaning and inspection of the engine for any signs of wear or damage. All wearable parts, including valves, are replaced while the cylinders are resurfaced to ensure maximum functionality. We revitalize the engine by replacing critical components such as the oil pump, timing belt, water pump, and bearings. The clearances are then meticulously checked to meet the specified standards. This all-encompassing process ensures that once finished, your engine will rival the performance of a brand-new counterpart, providing reliability for many years. Since the process of remanufacturing an engine is exhaustive, it is best handled by professionals.

Invest in our affordable engine remanufacturing services and keep enjoying your current car for years to come.

Revitalize Your Ride Today